CASE HISTORY

HomeCASE HISTORY

MIX@TRACTORCase History

Today farmers are confronted with a very important task: to produce food for a growing world population. The farm mechanization has to support work in the fields without affecting natural resources and protecting the health of everyone. For this reason innovative machines are required, machines that can carry out agricultural works with greater efficiency and safety.

The technology comes to help with two new specializations: mechatronics (the combination of mechanics, electronics and computer science) and connectivity (between man, machines and farm).

In agriculture the established connectivity standardis ISO 11783 ISOBUS. These modern technologies are not designed to alter agriculture, far more to help it going back to a “lean and clean” process that protects both farmers profitability and the environment.

MIX@TRACTORCase History

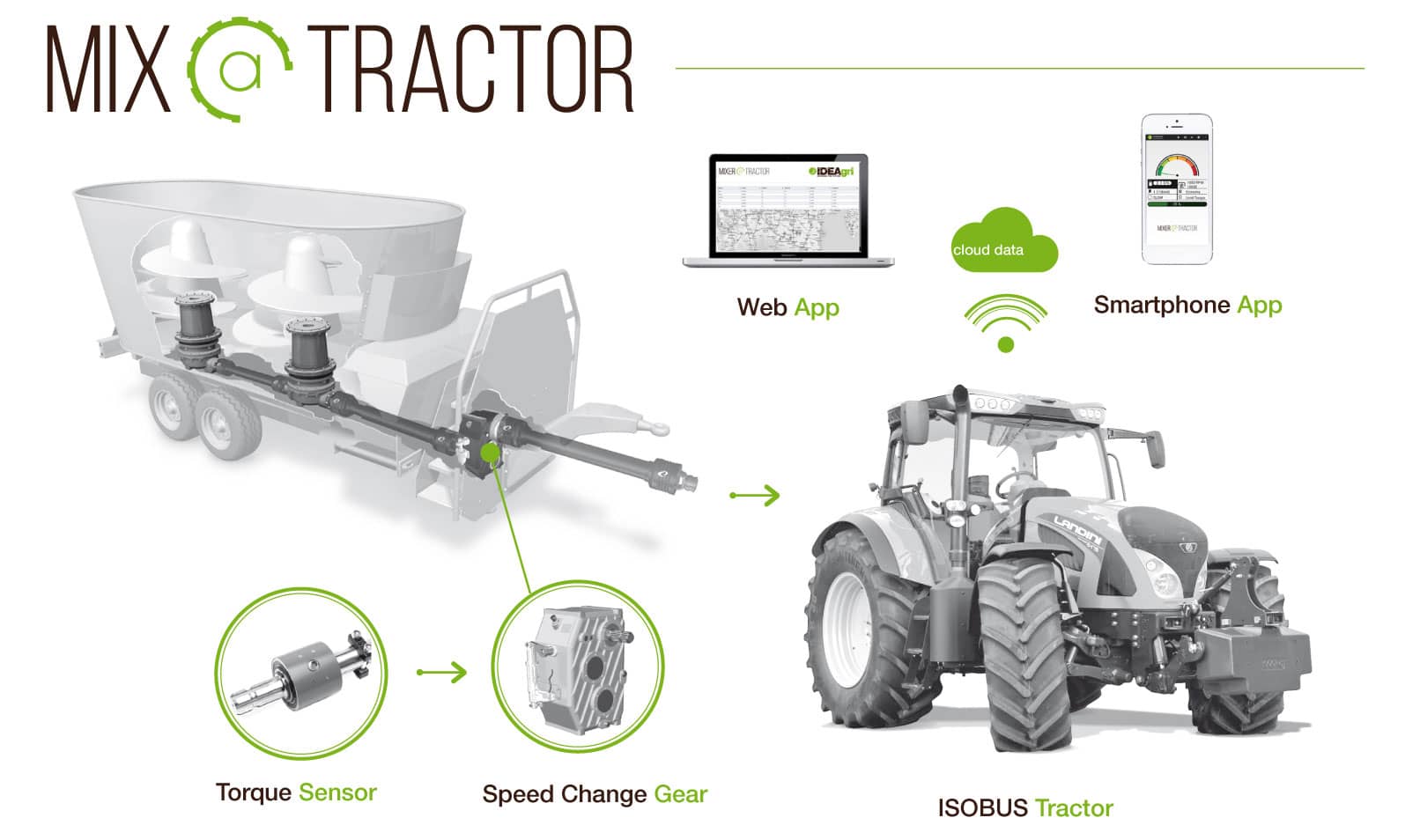

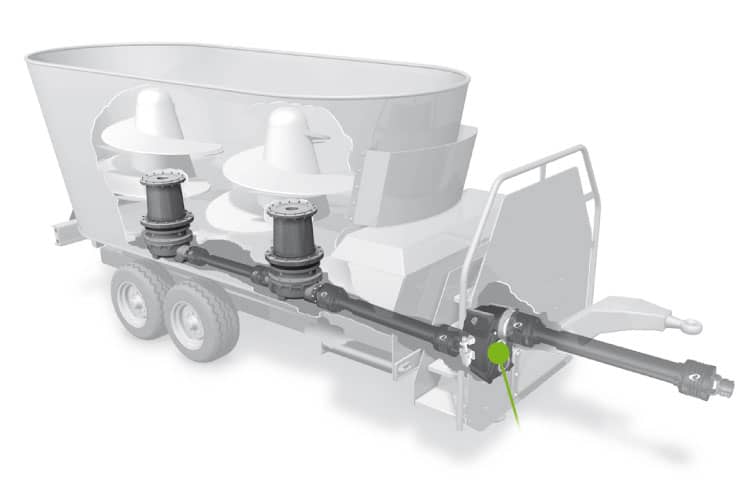

TheMIX@TRACTOR project sets out to show how using technologies that are already available today, mixing operations with trailed feed/mixers can be improved. In practical terms MIX@TRACTOR has two main objectives: to increase the efficiency of mixing (which means a lower consumption of diesel fuel and a shorter duration of the operation) and to improve the comfort and safety of the operator.

A Cruise Control for the Mixer

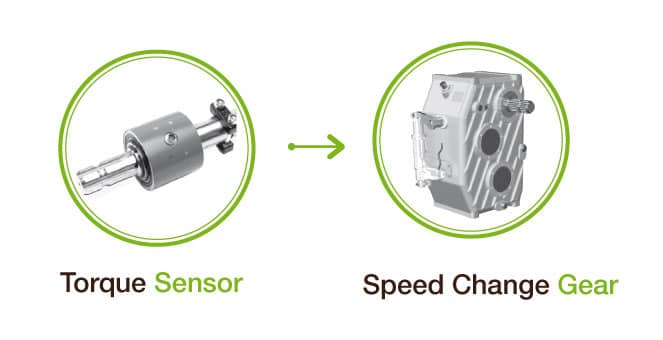

The use of a trailed mixer is rather easy. However, with the help of mix@tractor also less experienced operators can save up to 15% fuel and reduce the operating time. To achieve these goals, it takes only a few changes to be applied even to existing machines. The first ingrdient

is on the mixer: a speed change gear equipped with a torque sensor and an electric control of the gear shift. The second ingredient is on the tractor: a wireless gateway from ISOBUS to Bluetooth/GSM.

Operation

The mixing is normally divided into two phases: the filling of the mixer wagon and the actual mixing. During filling, MIX@TRACTOR operates in SAFETY mode, controlling the amplitude of the torque peaks in order to prevent damages to the mechanical transmission. Once filling is completed the real mixing phase starts. In this phaseMIX@TRACTOR operates in ECO FUEL and reduces consumption by autonomously managing gear shifts on the trailer and speed changes of the tractor PTO. The operator and the farm manager can monitor the progress of the mixing through the tractor’s ISOBUS Virtual Terminal, through smartphones and internet. All data are then stored in the Cloud and are accessible over the internet for statistics and accounting.